MEMS Sensor-Element Assembly Equipment

TCM-1000

MEMS sensor and electronic device assembly equipment Brand

Overview

- This equipment is equipped with MEMS sensor elements.

- Paste is applied to the PCB and MEMS sensor elements are mounted. Paste is applied to the electrode of the device, and then collected in the tray automatically.

Features

- Applying the technology cultivated in the crystal blank mounter, INDEX is used to make the device compact and to assemble high-performance parts.

- High-precision assembly is possible because the board/element position is measured by image processing and the position is corrected for assembly.

- Image processing is used to inspect the coating mass and condition to minimize the outflow of defects.

- Laser displacement meters measure board height to minimize variations in coating quality.

Usage examples

- In addition to MEMS sensors, we can also assemble small electronic devices such as capacitors, LEDs, human sensor, and photoelectric sensors.

- We will design according to the customer's request.

Please contact us.

Product Specifications

| ITEM | DETAILS |

|---|---|

| Model | TCM-1000 |

| Target workpiece (substrate) | Various boards MIN□2mm to MAX□10mm (Other sizes are also available) |

| Target workpiece (element) | Various elements MIN□1mm to MAX□8mm (Other sizes are also available) |

| Glue | Conductive adhesives (silicon-based, epoxy-based, etc.) |

| Coating diameter | φ0.1 to φ0.6 (varies depending on the adhesive used) |

| Mounting Accuracy | Within ±30 μm |

| Image Position Compensation | Board position, element position |

| Imaging function | Coating diameter, element not mounted, element displacement, etc. |

| Supplying and discharging of parts | Tray (10-stage magazine) |

| Cycle time | Approx. 1.0 sec./piece (varies depending on process conditions) |

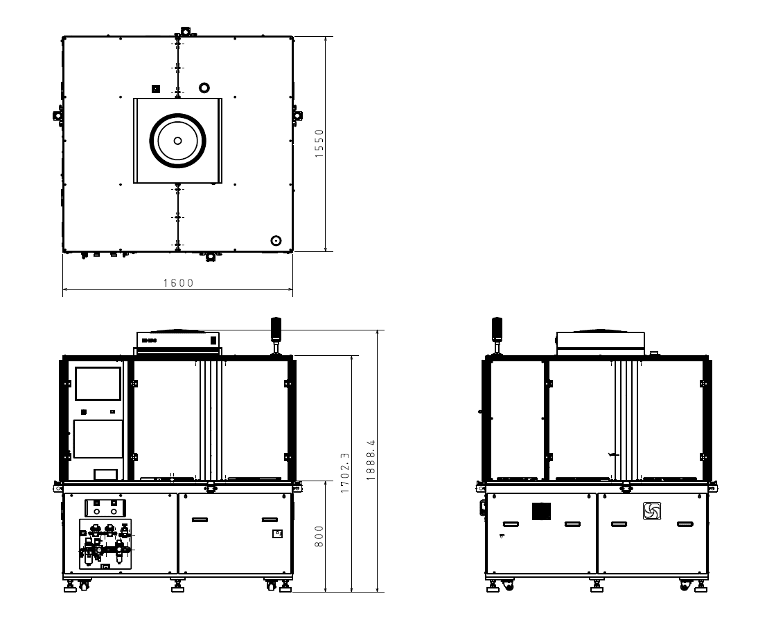

| Dimensions | W1650×D1550×H1700 mm (excluding patlite) |

| Equipment weight | Approx. 1500 kg |

*Configuration and specifications of this machine are subject to partial modification without prior notice.