Overview

- The transfer insertion equipment picks up packages, SMD type crystal devices, etc. sprinkled on trays, and after image measurement and position correction, transfers them to the specified pallet.

- This equipment transfers packages, SMD type crystal devices, etc. from pallets to pallets with different pitches and numbers.

- The Mask Placer also can be used to transfer to and arrange miniature chips on trays, etc.

Features

- This equipment recognizes workpieces such as packages and SMD type quartz crystal scattered in trays, picks up them with suction nozzles, measures the image of the adsorption workpiece, and transfers and inserts them into the specified pallet after position correction.

- This equipment transfers packages, SMD type cryastal devices, etc. from pallets to pallets with different pitches and numbers.

- Packages and devices on pallets may be separated in the manufacturing process, and may be manually refilled, or the pallets may be refilled into other pallets in the technology and development departments. This equipment reduces the man-hours required for this operation. It is a convenient work-filling equipment to have one unit in the Development Department and Technology Department, and one unit in the manufacturing plant.

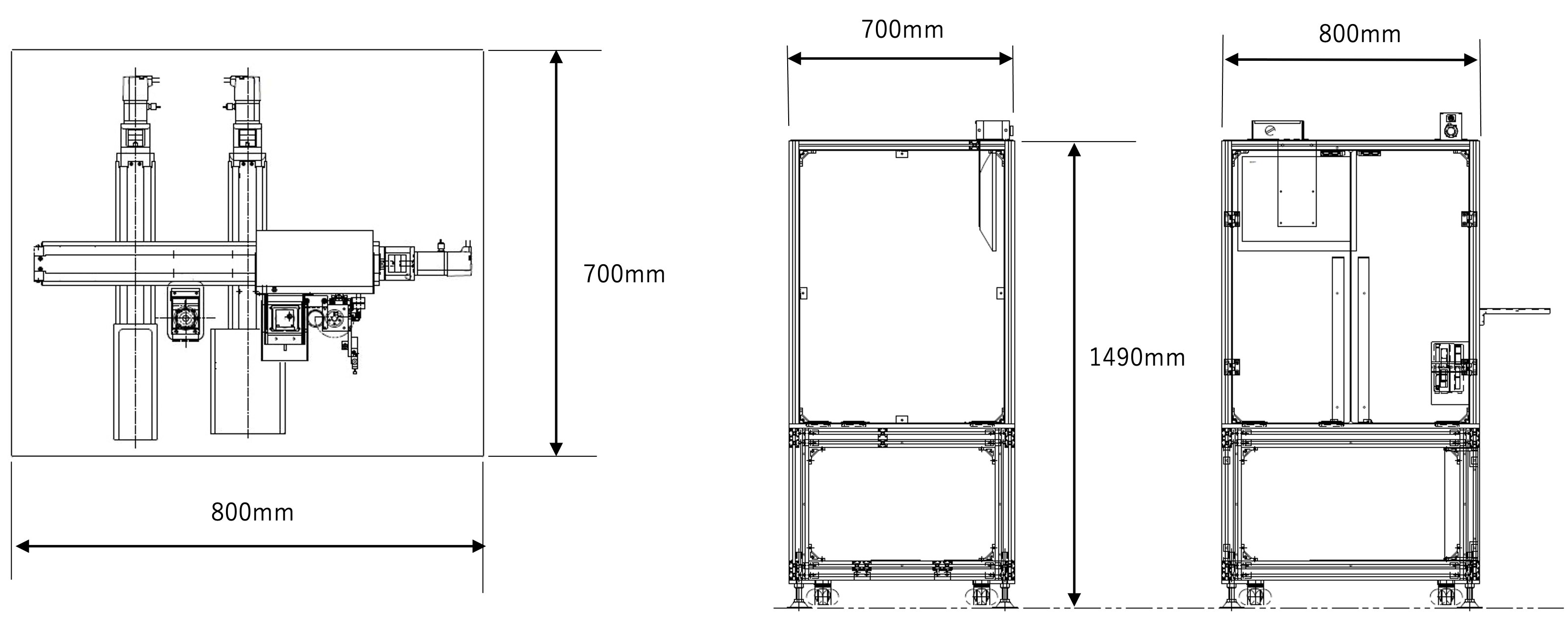

- This compact device has a small installation space of 800mm (W) ×700mm (D) ×1490mm (H).

Usage examples

In the manufacturing process because the packages and devices on the pallet become loose, they can be refilled manually, and in the technical and development departments. Pallets may be refilled into other pallets. This manual work will be done by this equipment.

Option

Various dedicated sub-trays can be used for transferring small chip parts from pallets with different pitches to pallets.

Product Specifications

| ITEM | DETAILS |

|---|---|

| Target workpiece | Package, SMD type crystal device, lid, etc. |

| Target workpiece size | 3.2×2.5, 2.5×2.0, 2.0×1.6, 1.6×1.2, 1.2×1.0, 1.0×0.8 (mm) * However, the standard specification is three varieties with close dimensions. |

| Image position correction | Pallet position correction on the storage side, target workpiece position correction and rotation direction correction |

| Work supply | Flat tray (loose tray) or pallet |

| Work storage | Supplying pallets by setting them in dedicated sub-trays |

| Cycle time | Approx. 2.0 sec./pc. |

| Insertion rate | 98% or more |

| External Dimensions | W800×D700×H1490 mm (excluding protruding objects such as a HEPA FILTER and PATLITE) |

| Option | Various dedicated sub-trays can be used for transferring small chip parts from pallets with different pitches to pallets. |

*Configuration and specifications of this machine are subject to partial modification without prior notice.