Overview

- This machine applies glue to sensor board and then mounts lens holders on them.

- Accurate mounting beyond that of conventional devices is now possible using image processing compensation and optical linear scale and high spec camera.

- Machine has achieved clean Class 100

Features

- Linear scale and 2 million pixel camera are adopted for the mounting process axis, and high-precision mounting (±10μm) is realized.

- Equipped with a twin dispenser and a high-speed mount head, a standard tact of 1.7 seconds per piece (*) is achieved.

*In case of optimum operating conditions: Need to discuss operating conditions - Cleanliness class 100 is achieved even during operation through thorough clean-up measures. Contamination defects are reduced by the neutralization and dust removal functions of workpieces.

- It is also very simple to create coating and mounting data for new models.

It supports three languages: Japanese, English, and Chinese.

Usage examples

This is the best device for VCM assembly that does not require active alignment.

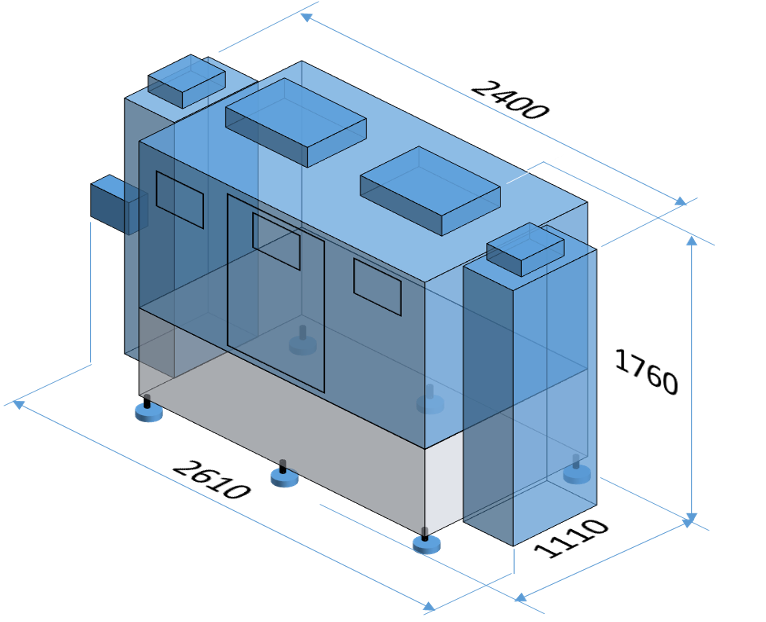

Product Specifications

| ITEM | DETAILS |

|---|---|

| Target sensor substrate | CCD/CMOS Sensor Board Size: L=50~250mm, W=40~100mm |

| Object lens holder | □ 5 to 10 mm/tray supply (with/without lens barrel) |

| Dispenser for adhesive application | ×2 units |

| Onboard head | ×1 unit |

| Adhesive application accuracy | ±35μm |

| Equipment Precision | ±10μm |

| Output | UPH ≧ 1600 |

| Imaging feature | CCD camera: 4 sets Work alignment, board direction determination, bad mark detection, application presence/absence detection, holder direction determination, etc. |

| Cleanliness inside the equipment | Class100 |

*Configuration and specifications of this machine are subject to partial modification without prior notice.