Overview

This machine is a fully automatic device that applies UV curing adhesive to the VCM unit of the camera module, inserts the lens barrel, and fixes the glue by UV irradiation.

Features

- This machine can process continuously from reading 2D code of VCM and lens to glue application, lens barrel mounting, and UV curing.

- Apply UV-curing glue for fixing the lens barrel after position correction with the image sensor.

- When the lens barrel is inserted, the position is corrected by the image sensor before mounting.

- The automatic correction function of the application pressure and the image sensor perform the application inspection before mounting the lens barrel.

- The cleanness is class 100 compliant.

Usage examples

Ideal for incorporating lens barrels into VCM

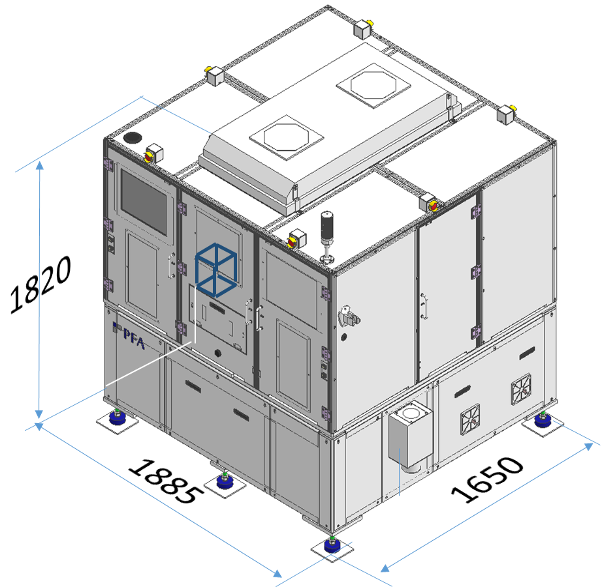

Product Specifications

| ITEM | DETAILS |

|---|---|

| Target workpiece size | VCM max.□16mm or less, height 8mm or less, soft tray feeding Barrel max φ12mm or less, height 6mm or less, soft tray feeding |

| Storage of finished products | JEDEC hard tray stacking |

| Adhesive application method | Air pulse dispenser GAP measurement function and application inspection function |

| Accuracy of Barrel mounting | XY±25μ or less |

| UPH | UPH600 (when UV-irradiation duration = 2 sec.) |

| Cleanliness | ISO Class5 0. 5μm range (Fed. Std 209D class-100 or equivalent) *Measurement near the workpiece on the index |

| Data management | VCM 2D cord and lens barrel 2D cord are linked and output to the file. INPUT count, Output count, process start time, process end time, XY-coordinate on Tray, magazine Slot No, etc. |

*Configuration and specifications of this machine are subject to partial modification without prior notice.