Overview

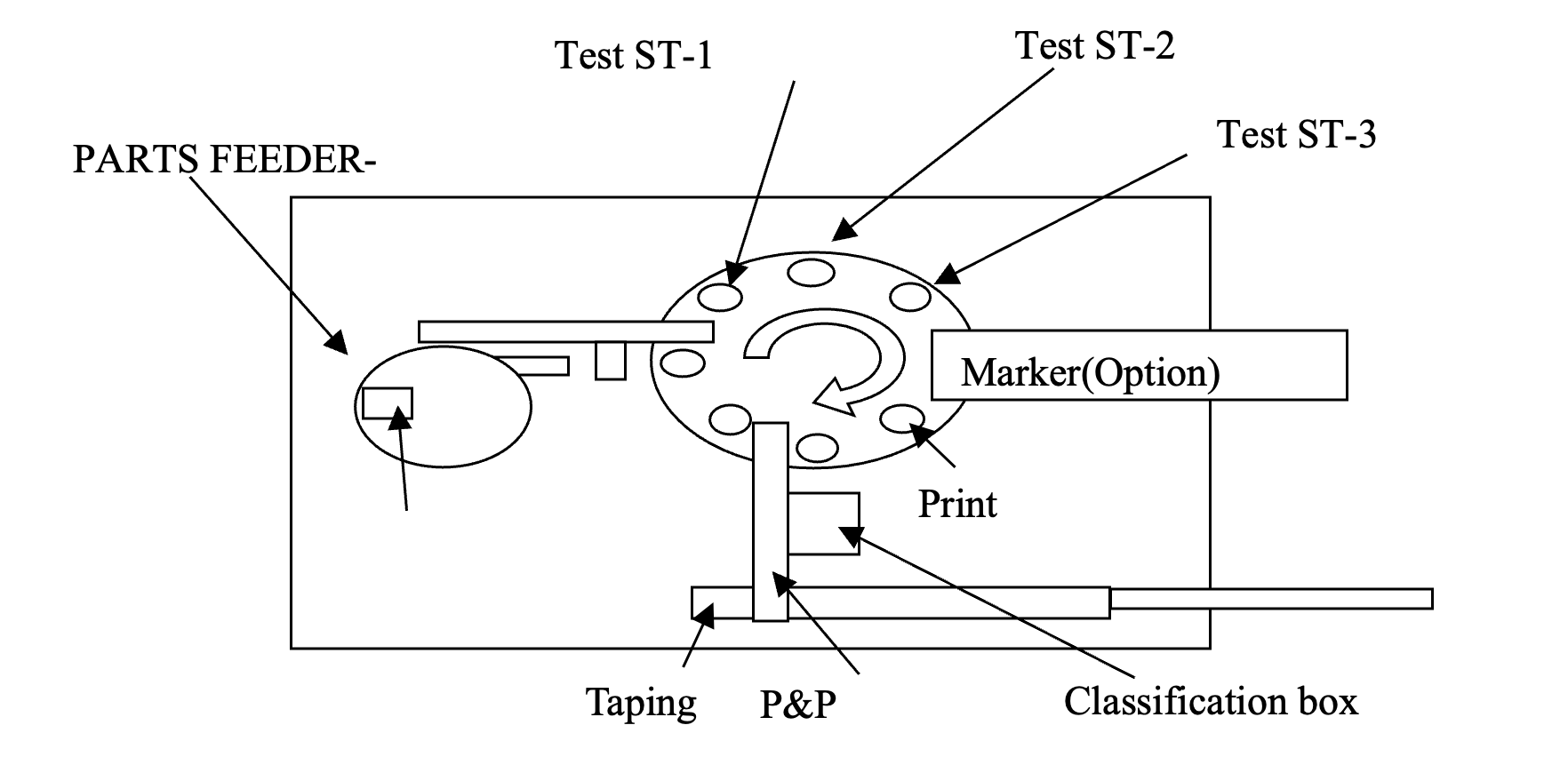

- This is a device that performs normal temperature inspection, printing inspection, and taping of SMD crystal oscillators at high speed.

- Especially for small workpieces, stable inspection, transportation and taping are realized.

Features

- Final inspection and taping equipment compatible with small SMD crystal resonators.

- As the final inspection of the SMD type crystal unit, the frequency and resistance value are inspected to determine the non-defective product and taping is performed.

- Stable inspection and transport are possible even for small worksize.

- As an option, you can add a laser printing function.

- As an option, you can add a gross leak check.

Usage examples

- Inspection and taping equipment compatible with small SMD crystal resonators.

- Frequency inspection and resistance value of SMD type crystal resonator are measured for pass/fail judgment.

- Laser printing can be done by adding an option.

- Only non-defective products are taped

Optional

- Optionally : Add to laser printing.

Product Specifications

| ITEM | DETAILS |

|---|---|

| Target workpiece | SMD crystal, 2016 |

| Target workpiece size | 3.2×2.5~1.0×0.8(㎜) |

| Inspection items | Frequency, resistance, drive level inspection, insulation inspection |

| Work supply | Parts feeder |

| Work storage | Taping (defective product: BOX) |

| External Dimensions | Standard-specification: W1200×D1100×H1500 mm (excluding protruding objects such as patlite) |

| Option | Laser printing |

*Configuration and specifications of this machine are subject to partial modification without prior notice.