Thermistor Mounter

PTM-1100

Crystal device manufacturing and thermistor mounting machines Brand

Overview

- This assembly device mounts a thermistor chip by applying glue or cream solder to the package of the SMD type thermistor crystal.

- The thermistor chip is supplied by an electric tape feeder.

Features

- Since the package position and thermistor position are measured by image processing and mounted with position correction, high-precision assembly is possible to accommodate even small packages.

- This equipment realizes high-precision measurement by adopting a digital camera and new lighting, and contributes to improving the quality of products through measurement and inspection using our original image processing system.

- High rigidity is improved by adopting a frame, a base integrated structure, and casting, and a tact time of 0.75 seconds/piece is realized.

- This equipment has improved IoT/ quality/self-diagnosis functions such as managing the times and frequency of use of main parts and consumables, and managing the hours and frequency of application of adhesive or cream solder.

- Can be tabulated from measured data. In addition, it is possible to record up to 50 image results taken by each camera, contributing to defect analysis.

Usage examples

- This assembly equipment mounts a thermistor by applying glue or cream solder to the package of SMD type X'tal device.

Option support

- In-line connection with the curing furnace (1 unit mounted and 1 unit curing furnace connected)

- Mechanism for periodically cutting the reel tape discharged from the tape feeder

Product Specifications

| ITEM | DETAILS |

|---|---|

| Target workpiece | SMD type thermistor crystal |

| Target workpiece size | 3.2×2.5, 2.5×2.0, 2.0×1.6, 1.6×1.2, 1.2×1.0 (mm) * However, the standard specifications are three varieties with close dimensions. |

| Thermistor chip size | 0.6×0.3、0.4×0.2(㎜) |

| Adhesive | Cream solder, conductive adhesive |

| Thermistor mounting accuracy | 3σ: ±50 μm or less (with respect to the target) |

| Image position correction | Package (position) measurement, thermistor (position) measurement |

| Image inspection function | Coating amount, application position, thermistor mounting position (thermistor position shift), thermistor not mounted |

| Supply and discharge of parts and materials | Package: Parts feeder or tray (set in 10-stage magazine), thermistor: Electric tape feeder, discharge (storage): tray (set in 10-stage magazine) |

| Cycle time | Approx. 0.75 sec./pc. or less (for 2-point application) |

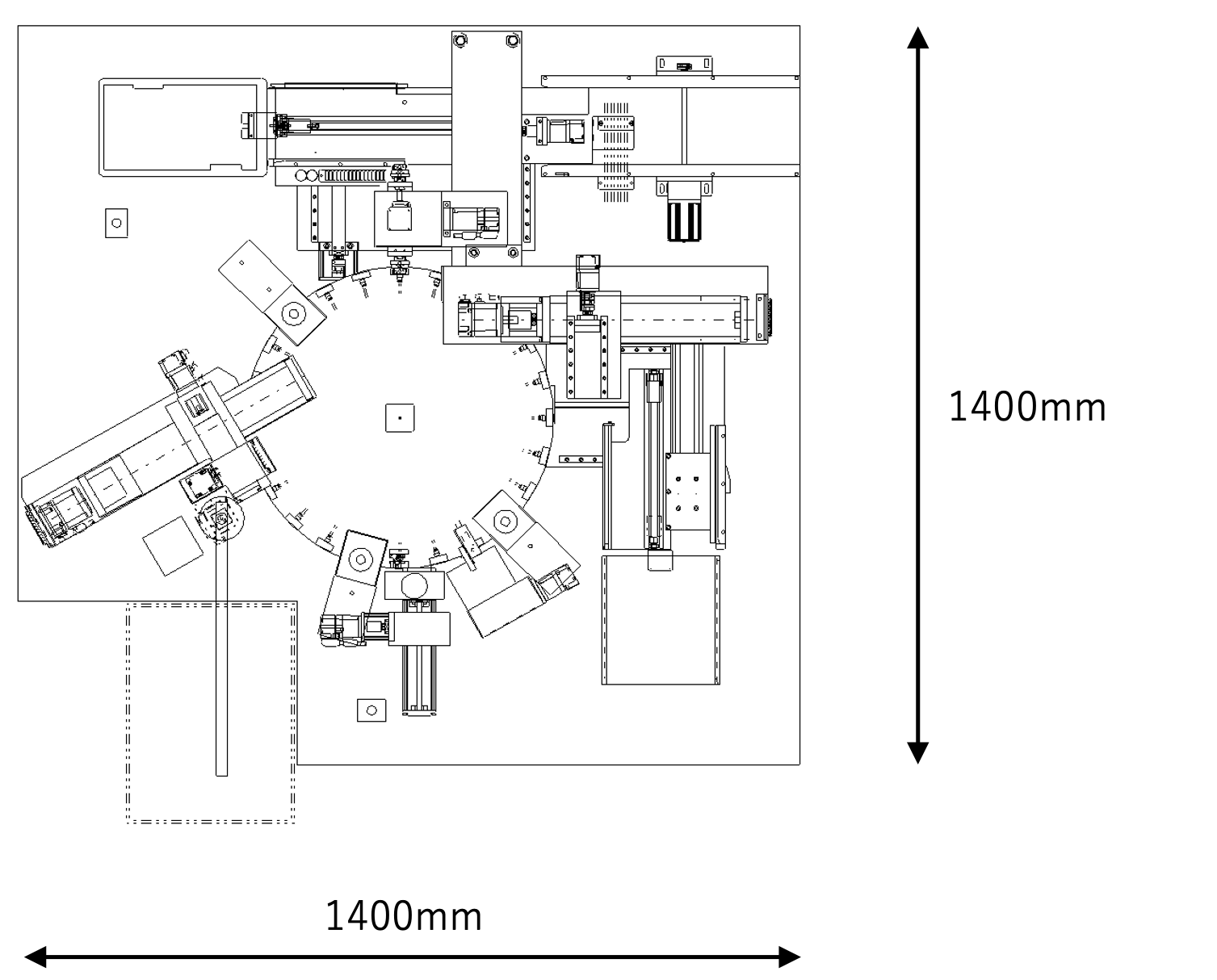

| External Dimensions | W1400×D1400×H1700 mm (excluding protruding objects such as a HEPA FILTER and PATLITE) |

| Option | Hardening furnace and in-run connection possible |

*Configuration and specifications of this machine are subject to partial modification without prior notice.