Overview

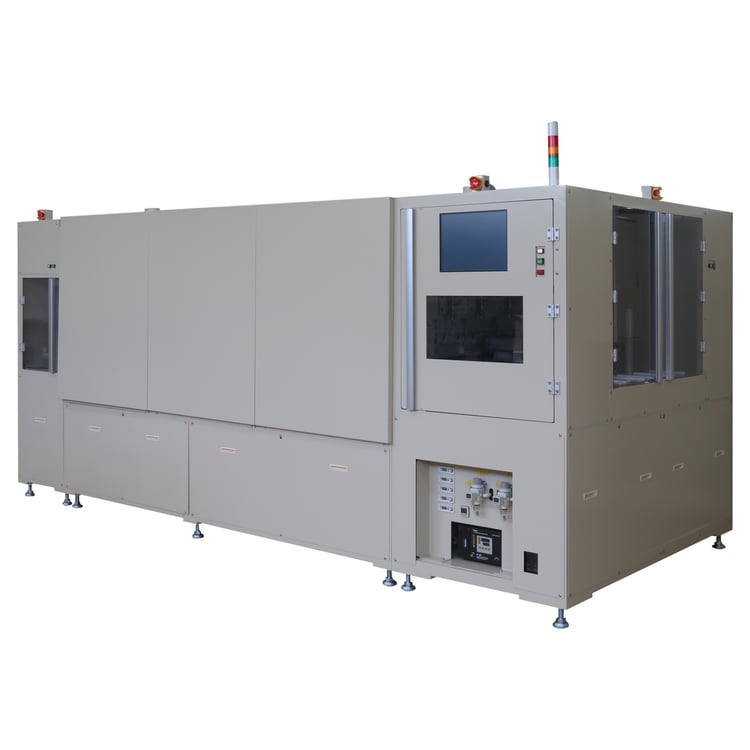

- This equipment heats conductive glue of quartz devices (oscillators, filters, etc.) arranged in metal trays in a clean N2 atmosphere controlled to a constant temperature curve and then dries and cures them.

- In-line connection with Blank Mounter

- The unloader stores the metal tray coming out of the furnace in a special magazine.

Features

- There is a stable atmosphere heating furnace with a hot air circulation method via a HEPA filter, and a heater block type (tray direct heating) curing furnace that can handle steep temperature gradients.

- The hot air circulation method can be selected from the belt conveyor transfer method and the walking beam transfer method.

- The heater block type curing furnace is compatible with the walking beam method.

- The hot air circulation type walking beam curing furnace minimizes the generation of particles and enables heating in a cleaner atmosphere.

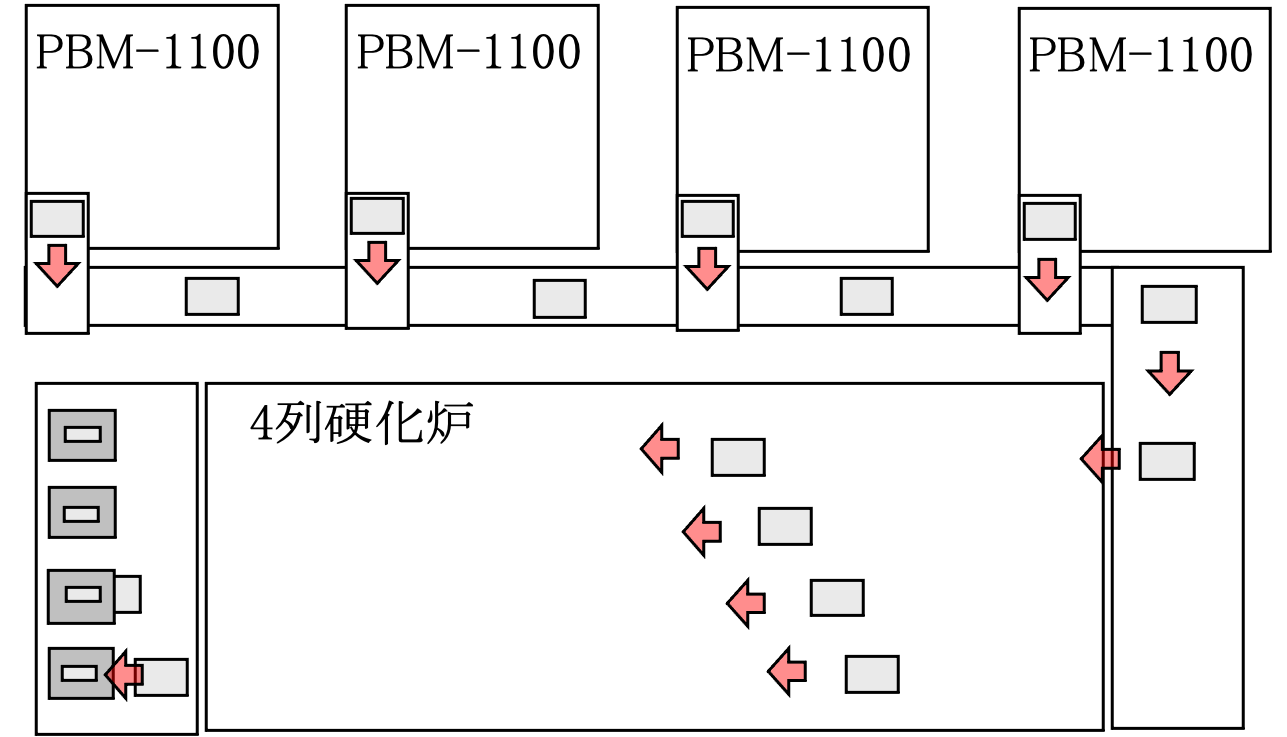

- The belt conveyor type hot air circulation furnace has a high production capacity, and up to four blank mounters can be connected to one curing furnace.

- Each heating furnace heats in an N2 atmosphere to prevent oxidation of the product.

Usage examples

- With a conductive glue of a crystal device (such as oscillator, or filter) arranged in a metal tray

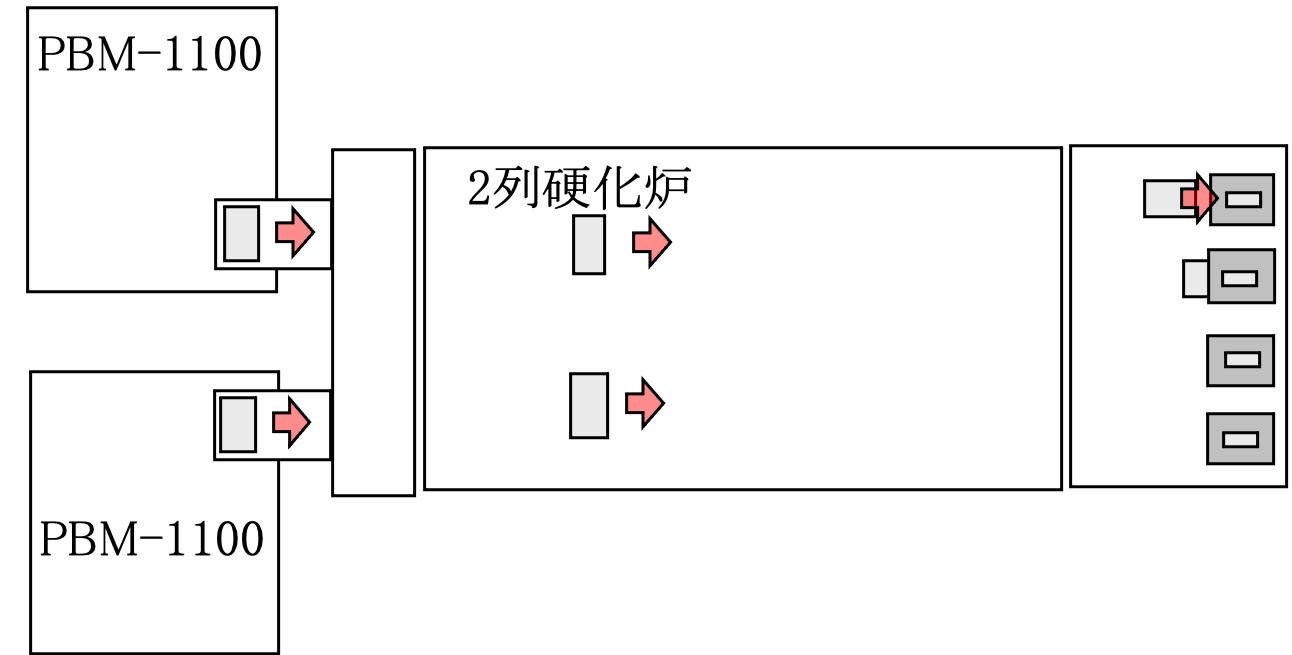

- In-line connection with multiple Blank Mounters is possible.

- The loader receives the metal tray carried out from the Blank Mounter and transfers it into the furnace.

- The unloader stores the metal tray coming out of the furnace in a special magazine.

[Optional]

- In the case of a belt conveyor type curing furnace, up to four units with blanks can be connected in-line.

- In the case of a walking beam curing furnace, up to two machines with blanks can be connected in-line.

- An oxygen densitometer can be attached.

Product Specifications

| ITEM | DETAILS |

|---|---|

| Target workpiece | SMD type crystal device (crystal resonator, crystal oscillator, crystal filter, etc.) |

| Temperature control | PID control (independent) * The number of zones varies depending on the temperature profile for each zone. |

| Temperature conditions | Maximum temperature: 320°C, Temperature accuracy: ±10°C |

| Conveying device | Belt Conveyor Type Continuous Feed Transport (SUS Mesh Belt + Quartz Belt Receiver), Walking Beam Type Transfer |

| Furnace atmosphere | N2 atmosphere, cleanliness class 100 or less, oxygen concentration 100ppm or less possible |

| Heating system | Belt type: Hot air circulation method Walking beam: Hot air circulation method / heater block method |

| Supply and discharge of parts and materials | Supply and discharge SUS tray in-line |

| External Dimensions | The external dimensions of the curing furnace depend on the temperature profile conditions and the tray outline. Reference dimensions: (W3630) × (D1650) × (H1670)mm (excluding protrusions such as patlite) |

| Option | Inline connections with Blank Mounter are possible. Oxygen densitometer is available. |

*Configuration and specifications of this machine are subject to partial modification without prior notice.

Installation dimensions

For installation dimensions, please contact us here.