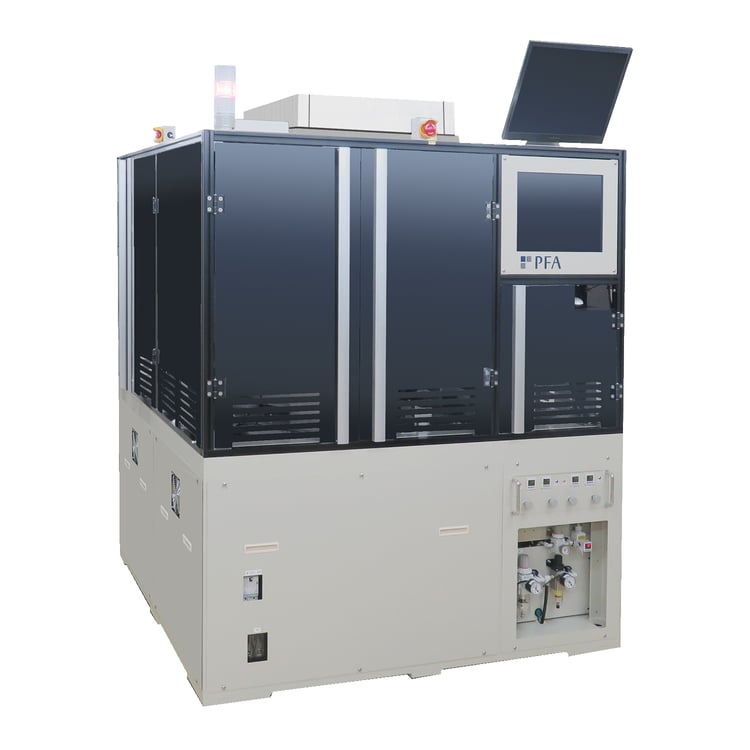

Overview

- This is the industry's highest-level device with a tact of 0.7 seconds, in which a crystal blank is mounted by applying an glue to the package of an SMD-type crystal device.

- We also offer a lineup of equipment for picking up and mounting chips directly from crystal wafers.

Obtained Japanese Patent No.4949937. - We have relentlessly pursued revisions to this product in order to improve ease of use and mounting accuracy, which has established it as the top product in the industry since its launch.

Features

- This high-precision, high-function mounter is compatible with small PKGs such as 1612/1210/1008.

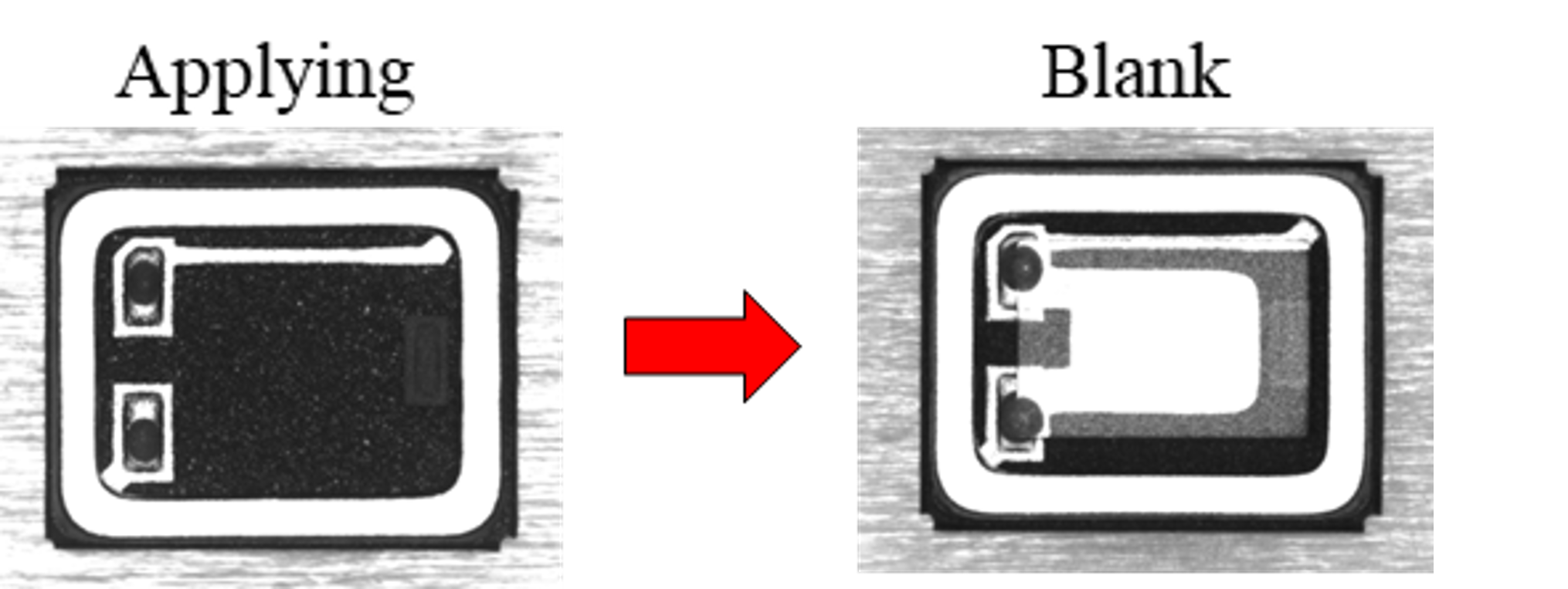

- This equipment realizes high-precision measurement by adopting a digital camera and new lighting, and contributes to improving the quality of products through measurement and inspection using our original image processing system.

- High rigidity is improved by adopting a frame, a base integrated structure, and casting, and a tact time of 0.7 seconds/piece is realized.

- This equipment is equipped with improved IoT/ quality/self-diagnosis functions, such as managing the times of use and frequency of use of main parts and consumables, and managing the hours and frequency of application of glues.

- Can be tabulated from measured data. In addition, it is possible to record up to 50 image results taken by each camera, contributing to defect analysis.

Usage examples

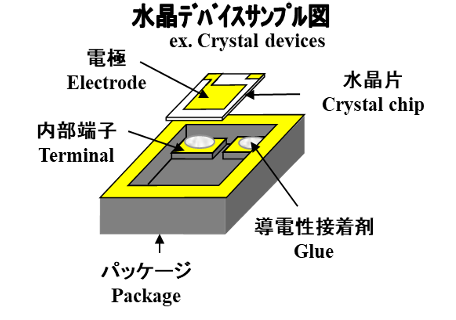

- This assembly device mounts a piece of quartz (blank) by applying glue to the package of SMD type crystal device.

[Optional] - Two-station mechanism of the coating unit

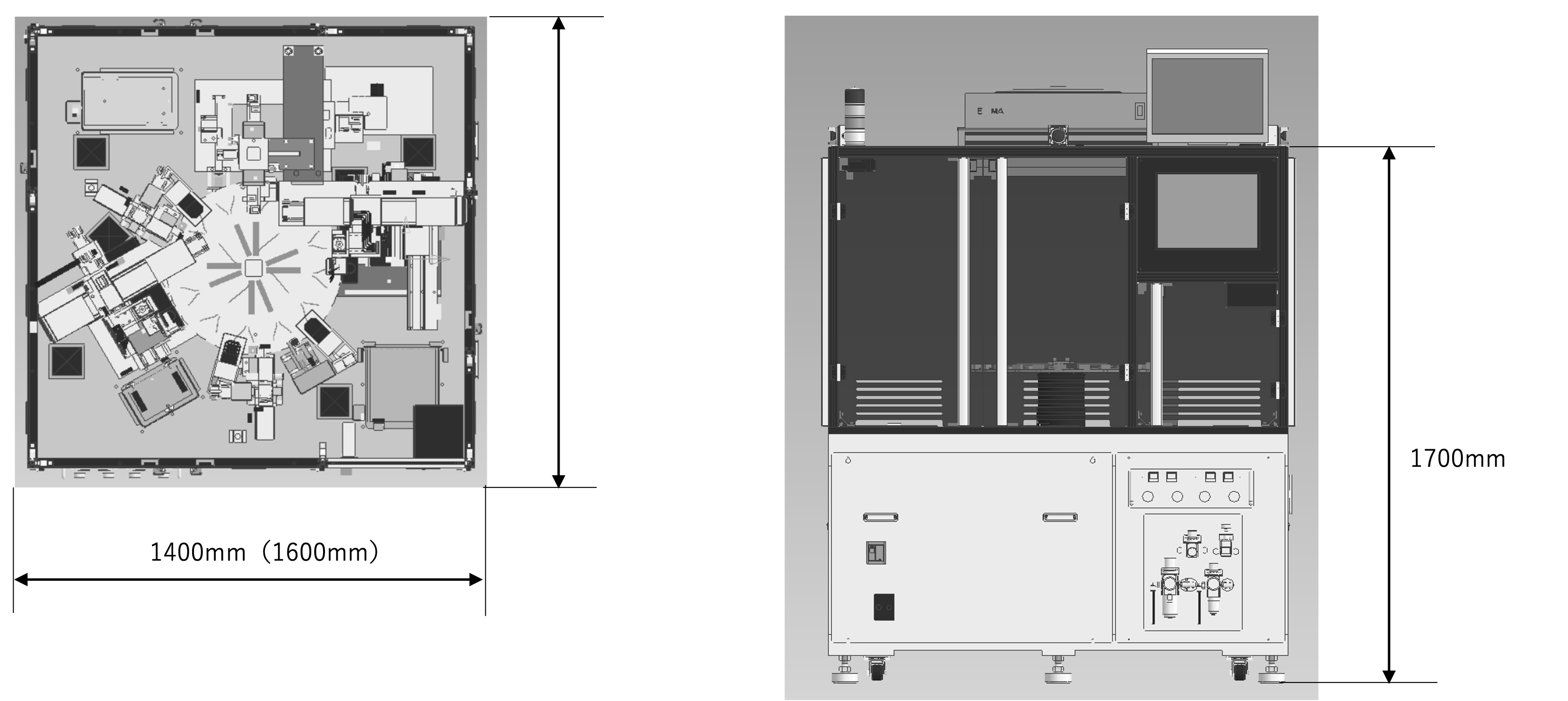

- Mechanism for folding crystal chips from quartz wafers of 4-inch size or smaller and mounting the folded quartz chips on packages coated with glue.

Obtained Japanese Patent No.4949937. - A function to measure the difference in height between the package seal surface and the blank surface with a laser displacement meter after mounting a crystal piece (blank).

- Expansion of target varieties

- In-line connection with a clean curing furnace is possible (4 units mounted and 1 curing furnace are connected, and 2 units mounted and 1 curing furnace are connected)

Product Specifications

| ITEM | DETAILS |

|---|---|

| Target workpiece | SMD type crystal resonator and oscillator |

| Target workpiece size | 3.2×2.5, 2.5×2.0, 2.0×1.6, 1.6×1.2, 1.2×1.0, 1.0×0.8 (mm) * However, the standard specification is three varieties with close dimensions. |

| Adhesive | Conductive adhesives (silicon-based, epoxy-based, etc.) |

| Coating mass | 3σ: φ150 μm ± 30 μm (PFA-designated adhesive, use of needles) |

| Accuracy of application position | 3σ: Within ±30 μm |

| Blank mounting accuracy | 3σ: Within ±30 μm |

| Image position correction | Package (position) measurement, blank (position) measurement |

| Image inspection function | Coating amount, application position, blank mounting position (blank position shift), blank not mounted |

| Supply and discharge of parts and materials | Tray (set in 10-stage magazine) |

| Cycle time | Standard specifications: Approx. 0.7 sec./pc. or less (for 2-point application) With chip folding mechanism of quartz wafer: Approx. 1.0 sec./pc. or less (for 2-point coating) |

| External Dimensions | Standard-specification: W1400×D1400×H1700 mm (excluding protruding objects such as a HEPA filter, monitor, or patlite) With chip-folding mechanism for quartz wafers: W1600×D1650×H1700 millimeters (excluding protrusions such as hemp filters, monitors, and patlites) |

| Option | Clean curing furnace and in-run connection possible |

*Configuration and specifications of this machine are subject to partial modification without prior notice.

.png?width=750&name=PRO-series(new).png)