Overview

High Speed Wire Bonder adaptable to wide frames and suitable for LED and discrete production

Features

- Platform featuring high speed bonding of 42ms/0.7mm (45ms/2 mm) with completely updated X, Y and Z motors

- Bonding accuracy of±3.0μm(3σ)achieved

- Capable of indexing 102mm x 300mm lead frames by allowing Y bonding area of 95mm

- Simultaneous detection and bonding capability in X and Y directions

- Applicable to Cu wire due to addition of Cu kit

Usage examples

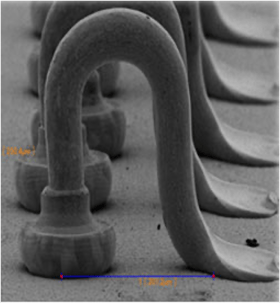

Connect with chain bonds: Capillary Wedge Bonding (CWB)

NAND flash memories, widely used as a storage medium such as the familiar USB memory stick, and for large-scale cloud servers, are produced by stacking many dies for increased capacity. Signals from the stacked dies are transmitted through bonded fine metal wires. Conventionally, to bond wires on stacked dies, it is necessary to bond the wire, terminate it, and then bond additional wires on the subsequent steps. This is a time-consuming task and has been one of the productivity bottlenecks in NAND flash memory production.

We have developed a high speed bonding method using CWB and CWB with bump (CWBB) technologies which allows multi-stack wire bonding in a single, continuous cycle without terminating wires. We continue to refine this technology so that a wide range of customers can benefit from its short cycle time.

From connecting to making: the wire bonder as electronic device manufacturing equipment

Conventionally, a wire bonder has been widely used as a machine for connecting electrical signals. The connecting demand will never go away, and in fact, it has propelled us to create a wire bonder that can place and shape wires freely. Its capability allows the wire bonder to evolve into an electronic component manufacturing machine by creating coils – important parts of electronic components.

For example, it is possible to create coils with specific impedance or create supplementary coils for circuit adjustment. We are continually working on new challenges based on wire bonding technology.

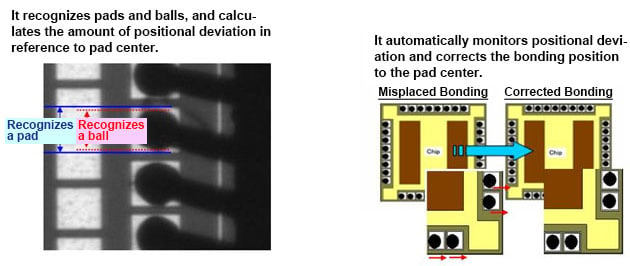

Bond Inspection Measurement (BIM)

BIM is the capability to correct bonding position by feedback of the positional deviation of each bonding position from the pad center using images captured after bonding. It corrects in real time any positional deviation due to disturbances during the bonding operation, and stabilizes the bonding accuracy.

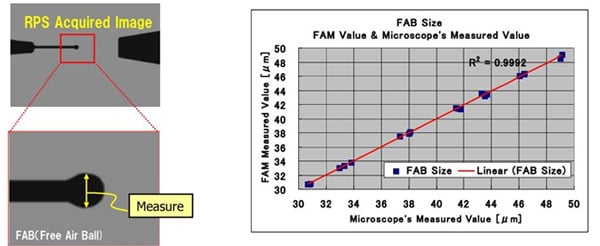

Free Air Ball Measurement (FAM): Automatic free air ball size monitoring capability

FAM is our unique technology which monitors free air ball (FAB) diameter during wire bonding, and detects its abnormality at the same time, to stabilize the diameter. To detect abnormality, the function to monitor capillary tip position – called reference positioning system (RPS) – is utilized. FAM is a key technology to support the highly reliable bonding of the UTC-5000 series.

Product Specifications

| ITEM | DETAILS |

|---|---|

| Product Name | Wire Bonder |

| Model | UTC-5100 |

| Bonding Accuracy | ±3.0 μm (3 σ), (The bonding accuracy changes depending on the conditions of device and temperature) |

| Bonding Speed | 42 ms/0.7 mm wire (45 ms/2 mm wire) (with loop control and force detection mode) Using Shinkawa standard device |

| Bonding Wire Length | 4 mm maximum (Varies depending on device conditions) |

| Resolution | XY table: 0.1 μm, Z-axis: 0.1 μm |

| Vibration Control | Shinkawa NRS - Non Reaction Servo System |

| Bonding Area | X: 66mm - Camera offset, Y: 95mm - Camera offset |

| Wire Size | Au φ18–50 μm |

| Bonding Force | 3~1,000gf |

| No. of Bonding Wires | 12,000 wires maximum |

| Loader / Unloader | Fully automatic magazine stacker system (Option: stocker system) |

| Workpiece Size | Width 20~102mm Length 95~300mm Thickness 0.1 - 0.5 mm (Varies depending on type of device) (Conversion parts are required when thickness changes) |

| Production Management | Management of equipment availability through production management monitoring screen |

| Option Available | Communication interface SECS-I/SECS-II, HSMS, GEM |

| Utilities | Input Power Supply Single Phase 100VAC (±5% input variation) 50/60Hz (other voltages require transformer) Power Consumption Approx.1.2kVA (1.1kW) CDA 500kPa (5 kgf/cm2) 102L/min Vacuum -74kPa (-550 mmHg) or below (gauge) |

| Physical Dimensions and Mass | 1,244W × 964D × 2,092H mm Approx.520 kg |

※Configuration and specifications of this machine are subject to partial modification without prior notice.

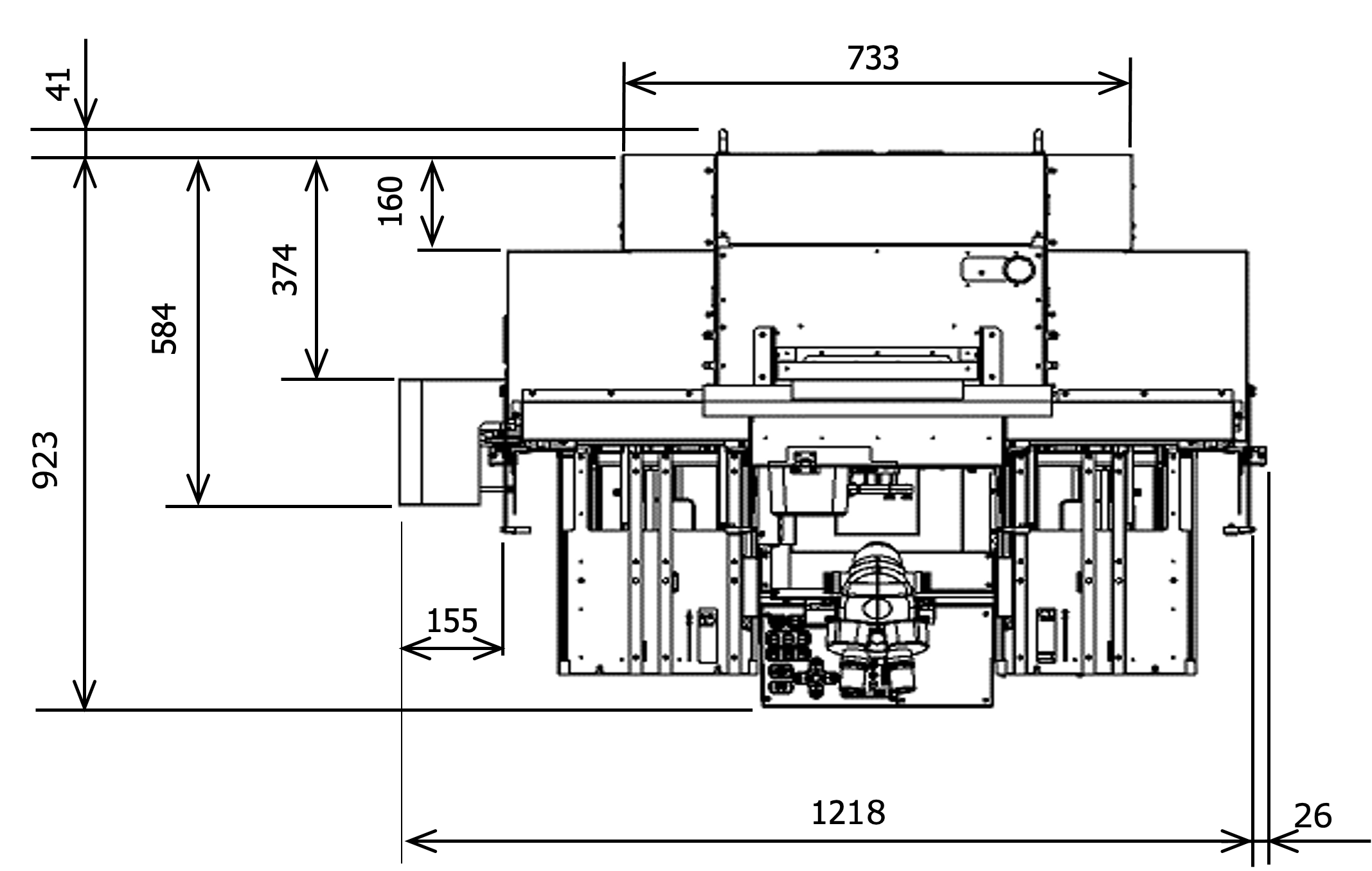

Installation dimensions

Related Products