Overview

Wide-area Adaptive High-speed Wafer Bump Bonder

Features

- High-speed bonding of 30 ms/bump based on Wire Bonder model UTC-5000

- Capable of handling up to 6-inch wafers by incorporating wafer rotary stage

- Equipped with Two wafer stages with temperature up/down control function, reducing time for SAW filter wafer changeover and increasing productivity

- Automatic free air ball monitor function (FAM) measuring initial ball diameter

- Wafer autoloader enables automatic wafer replacement (option)

Usage examples

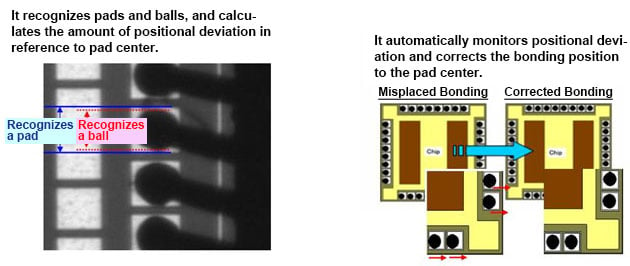

Bond Inspection Measurement (BIM)

BIM is the capability to correct bonding position by feedback of the positional deviation of each bonding position from the pad center using images captured after bonding. It corrects in real time any positional deviation due to disturbances during the bonding operation, and stabilizes the bonding accuracy.

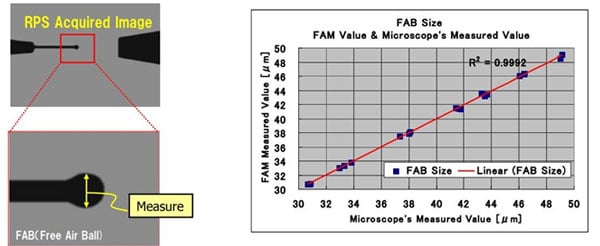

Free Air Ball Measurement (FAM): Automatic free air ball size monitoring capability

FAM is our unique technology which monitors free air ball (FAB) diameter during wire bonding, and detects its abnormality at the same time, to stabilize the diameter. To detect abnormality, the function to monitor capillary tip position – called Reference Positioning System (RPS) – is utilized. FAM is a key technology to support the highly reliable bonding of the UTC-5000 series.

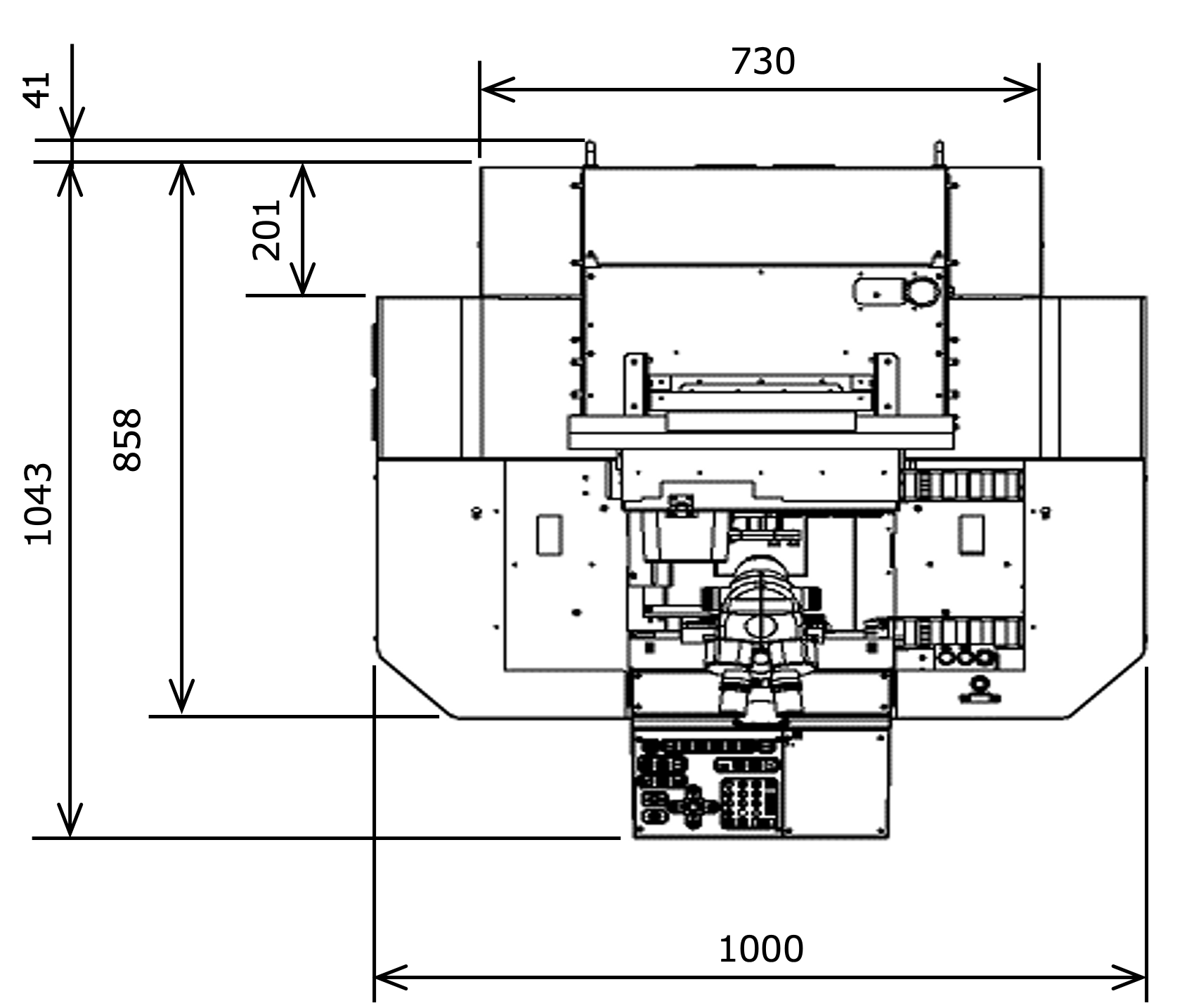

Product Specifications

| ITEM | DETAILS |

|---|---|

| Product Name | Bump Bonder |

| Model | SBB-5200 |

| Bonding Accuracy | ±2.5 μm(3σ)Using Shinkawa standard device |

| Correction of Bonding Position | System to check and correct capillary offset prior to bonding through Shinkawa RPS |

| Bonding Speed | 30 ms/ bump (no reverse motion) using Shinkawa standard device |

| Resolution | XY-table: 0.1 μm Z-axis: 0.1 μm |

| Vibration Control | Shinkawa NRS - Non Reaction Servo System |

| Bonding Area | Maximum φ150 mm (6-inch wafer) |

| Wire Size | Au φ15~32 μm |

| Bonding Force | Maximum 4.9N |

| No. of Bonding Bumps | 30,000 bumps maximum |

| Wafer Stage | 2 wafer stages for 6-inch wafers ※with temperature up/down control function |

| Wafer Size | Size Maximum 6 inches (Conversion parts are required when wafer size changes.) Thickness 0.15~0.6 mm(Conversion parts may be required when wafer thickness changes.) |

| Production Management | Management of equipment availability through production management monitoring screen |

| Options Available | Automatic wafer loader for 6-inch wafer |

| Utilities | Input Power Supply Single Phase 100 VAC (±5% input variation) 50/60Hz (other voltage requires transformer) Power Consumption Approx. 1.1kVA CDA 500 kPa(5 kgf/cm2)100 L/min Vacuum -74kPa or below (-550 mmHg) (gauge) |

| Physical Dimensions and Mass | 1,000W × 1,084D × 2,092H mm Approx. 500 kg |

*Configuration and specifications of this machine are subject to partial modification without prior notice.