Overview

This is an FC bonder using US bonding (ultrasonic waves).

Features

The increased efficiency of ultrasonic waves allows bonding at low temperatures and in a short time, to avoid mechanical and thermal stress on the product, which in turn enables stable, high quality bonding.

Usage examples

A load/ultrasonic wave head can be chosen according to the application of the material or product. And, thus this bonder can be used for products such as TCXO and SAW filters as well as LEDs and CMOS.

A maximum of 12 inch wafer can be handled if optional equipment is used.

Product Specifications

| ITEM | DETAILS | ||

|---|---|---|---|

| Model | AFM-15 | ||

| Type | 1505 | 1508 | 1562 |

| Joining Method | Heating,ultrasonic | ||

| Object Product | LED,TCXO,SAW,RF,MEMS,CMOS etc. | ||

| Target Chips | MAX:2.5 W × 2.5D × 1.0T mm MIN:0.3W × 0.3D × 0.1T mm (Option:20.0W × 20.0D mm) | MAX:7.0 W × 7.0D × 1.0T mm MIN:2.5 W × 2.5D × 0.1T mm (Option:20.0W × 20.0D mm) | |

| Target Submount | MAX:180W × 120D×3.0Tmm MIN:50W × 50D × 0.3Tmm (Option:8inch wafer substrate) | MAX:170W × 105D × 3.0Tmm MIN:50W × 50D × 0.3Tmm | MAX:180W × 120D × 3.0Tmm MIN:50W × 50D × 0.3Tmm (Option:12inch wafer substrate) |

| Tact Time | 0.78sec/Chip (Including 0.2sec process time) | 0.59sec/Chip (Including 0.16sec process time) | 1.35sec/Chip (Including 0.4sec process time) |

| Mounting Accuracy | ±7μm/3σ (Option:±5μm,±3μm) | ±5μm/3σ (Option:±3μm) | |

| Maximum Load | 25N(Option:50N , 100N ,200N ,500N) | ||

| Chip Supply | 5",6",8",12"wafer-ring (option:12 wafer-ring ) | 5",6"wafer-ring | 8",12"wafer-ring |

| Automatic magazine Loader | Automatic magazine Loader | Automatic magazine Loader | |

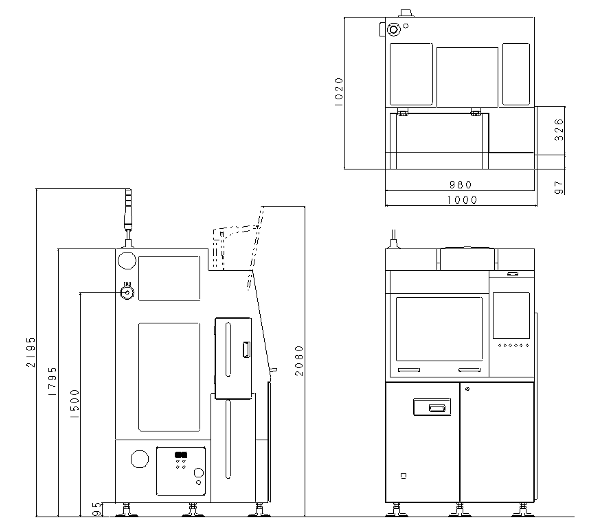

| Size | 1,200W × 1,504D × 1,650H mm | 980W × 1,040D × 1,860H mm | 1,980W × 1,620D × 1,566H mm |

| Weight | Approx. 1,800 kg | Approx. 1,500 kg | Approx. 2,100 kg |

| Standard Features | Preheating table(Warming) Mounting table(Warming) Automated mounting nozzle cleaning Ultrasonic power monitoring Chip height measuring Bump detection Detection of NG marking Adjustment for wafer rotational position Wafer sheet expander Hot air blower Monitoring of mounting nozzle tip condition LAN connection interface frequency counter of use of mounting nozzle Production data logging | ||

| Optional Features | Magazine , Loader and Unloader Neutralized air blower HEPA filter Mounting profile monitetor Compatible with chip supply tray Map data Mounting nozzle heater submount (or package) holder OK/NG judgment Nozzle polishing Jig | ||

*Configuration and specifications of this machine are subject to partial modification without prior notice.